As an innovative specialist involved in research&design,manufacture,engineering and technical service,ANDE has gained rich experience and achievement in crushing&sizing,vertical roller mill&grinding and palletizing technology,resulting in strong technical strength and market competitiveness.Through continuous innovation,ANDE is becoming a leading company of process equipment manufacture and engineering in metallurgy,power and mining.

Andi Metallurgical is committed to excellence, delivering high-quality products to customers and providing innovative metallurgical machinery solutions that lead market trends. To achieve a qualitative leap in its product R&D management capabilities, the company decided to establish a technology R&D system aligned with its rapid development and to build an enterprise-level product development management platform. After careful evaluation and selection, SPUR Software won high recognition from the company for its globally leading MDA technology and advanced lean development solutions, and was successfully selected as the supplier for Andi Metallurgical's R&D information management platform.

SIPM Software has long been dedicated to research, development, and practical application of R&D system methodologies and information platforms. Its Product Lifecycle Management System (SIPM/PLM) revolutionarily applies MDA technology to the PLM domain. The ultimate goal of the system is to institutionalize the enterprise's advanced management systems and methods, helping hundreds of companies enhance their R&D management capabilities and build effective information systems.

【Company Background】

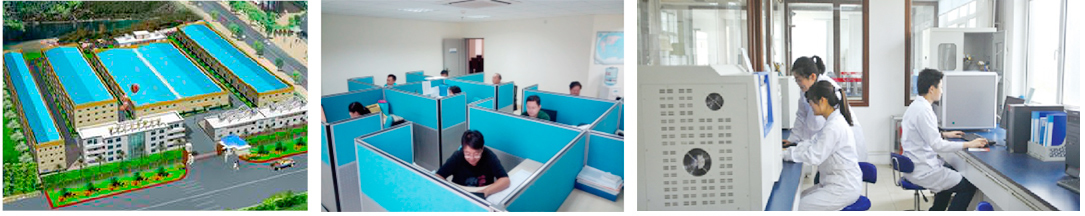

As an innovative specialist involved in research&design,manufacture,engineering and technical service,ANDE has gained rich experience and achievement in crushing&sizing,vertical roller mill&grinding and palletizing technology,resulting in strong technical strength and market competitiveness.Through continuous innovation,ANDE is becoming a leading company of process equipment manufacture and engineering in metallurgy,power and mining.

ANDE has about 150 employees,total of them about 40 with middle and senior professional titles,majored in metallurgy,mining,mechanical engineering design,mechanical process,welding,electrical,instrumentation,automation control and etc.It has strong research and design ability in metallurgy&mining equipment and system.

ANDE is located in Chengdong Industrial Park,Mingshui Economic Development Zone,Zhangqiu,Jinan.Plant covers an area of 3 hectares and construction area of workshops is 13000 m².

Registered capital is RMB 50 million,and annunal turnover was RMB 150 million in 2019.

Company has about 160 employees,out of which middle&senior title professionals constitute 30%.

ANDE was approved with ISO9001 quality system certification in 2006.

Since 2009,ANDE has introduced MPS VRM technology from Germany and CK mill technology from Japan,and engaged in design,manufacture and system integration of coal mill and BF slag mill.

So far,more than 90 sets of grinding and coal injection system have been put into operation in well-known domestic and overseas metallurgical enterprises,such as Benxi Steel,Jinan Steel,Sanming Steel,Jianlong,Jingye,Southern Nonferrous,TATA Metalliks and HZL of India.

Engineering Dept.was set up in 2010,dealing with engineering design and project management.Up to now,over 110 projects have been put into operation.

Awarded by Science&Technology Bureau of Shandong Province with“Engineering Technology&Research Center of VRM and Coal Injection for Furnace&Kiln”in 2014.

Awarded by Science&Tech Bureau of Shandong Province with“High-tech Enterprise”in 2015&2018.

Installation subsidiary of the company was established In 2017,with the qualification of"Grade III Contractor of Mechanical&Electrical Installation Engineering of Construction and Installation".

In cooperation with Beijing Metallurgical Equipment Design&Research Institute and Shandong Construction Material Design&Research Institute for many times,ANDE has contracted the design,supply,installation,commissioning&operation services of 6 lime kiln production lines on EPC basis.