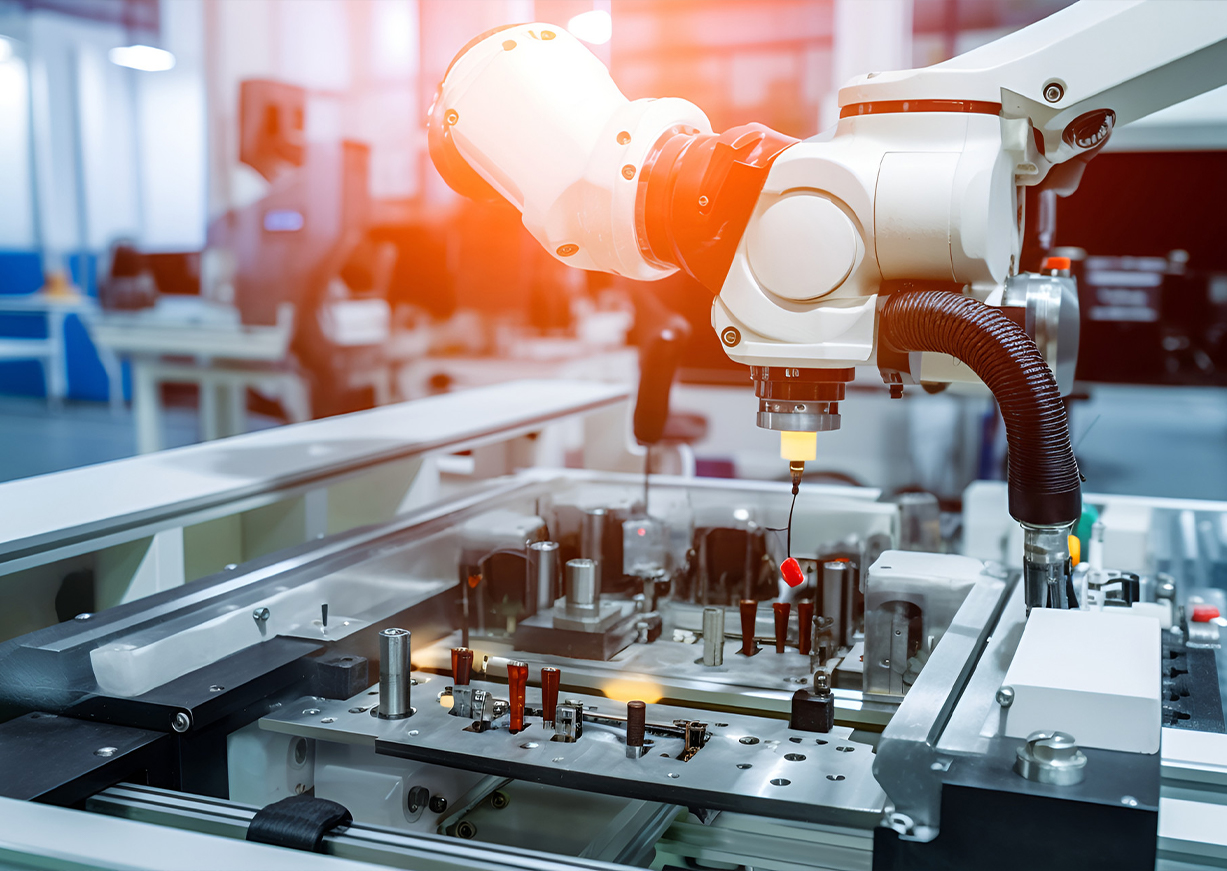

Prototype manufacturing is a critical phase in product development. However, in traditional models, frequent issues such as unclear requirements, inefficient inter-departmental collaboration, untrackable progress, and data silos often lead to prolonged trial cycles, high costs, and delayed deliveries. How can we break through this deadlock? The Prototype Manufacturing System (PMS) has emerged as the solution!

_1757557185345.jpg)

End-to-end dynamic management to create an efficient manufacturing closed-loop!

The PMS system centers on end-to-end management of the "Requirement → Prototyping → Delivery" process, covering design, BOM, process planning, materials, and production. It breaks down collaboration barriers across technical, production, procurement, and quality departments, and is deeply integrated with SIPM PLM system to achieve a seamless, "zero-gap" transition from design to prototyping, helping enterprises:

_1757382474997.png)

Usher in a New Era of Efficient Prototyping!

Whether developing new products or custom prototypes, PMS can inject "smart capabilities" into your prototyping process!

Simplify the complex and make prototyping more precise!

PMS, empowering enterprises to upgrade intelligent manufacturing!

- Online Communication