_1757381962697.png)

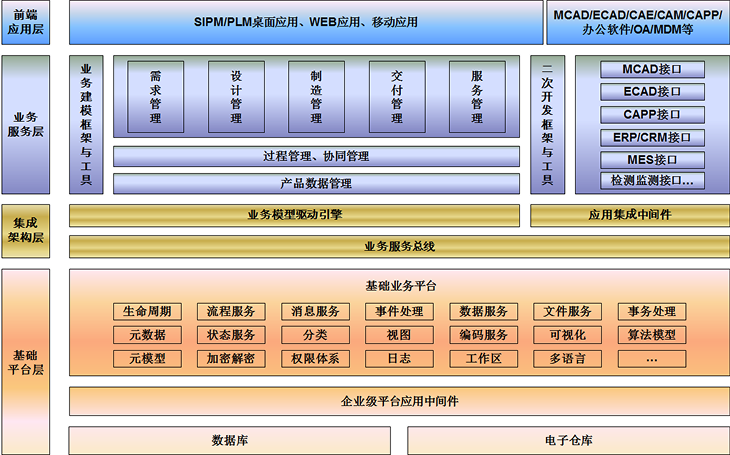

SIPM Product Life-cycle Management System

The Trinity Empowerment System: Reconstructing the enterprise R&D system from three major dimensions—process optimization, technology integration, and talent enhancement—to create a scalable digital management platform. This helps manufacturing industries achieve:

_1757497292630.png)

Cross-domain design collaboration

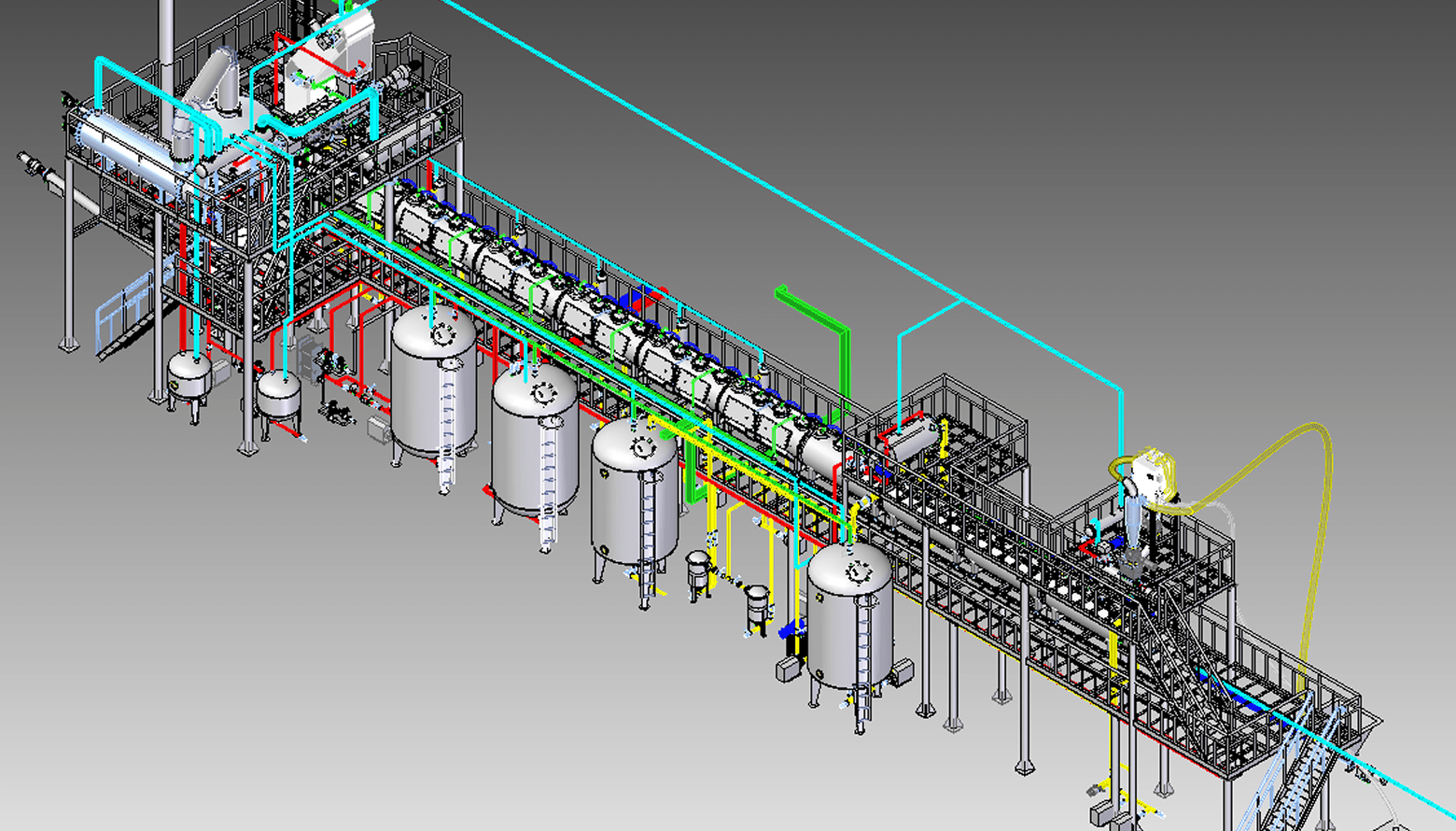

SIPM supports advanced research and rapid order development in the chemical industry,with AI-powered prediction of formulations and experimental outcomes,significantly enhancing the R&D efficiency of chemical products.

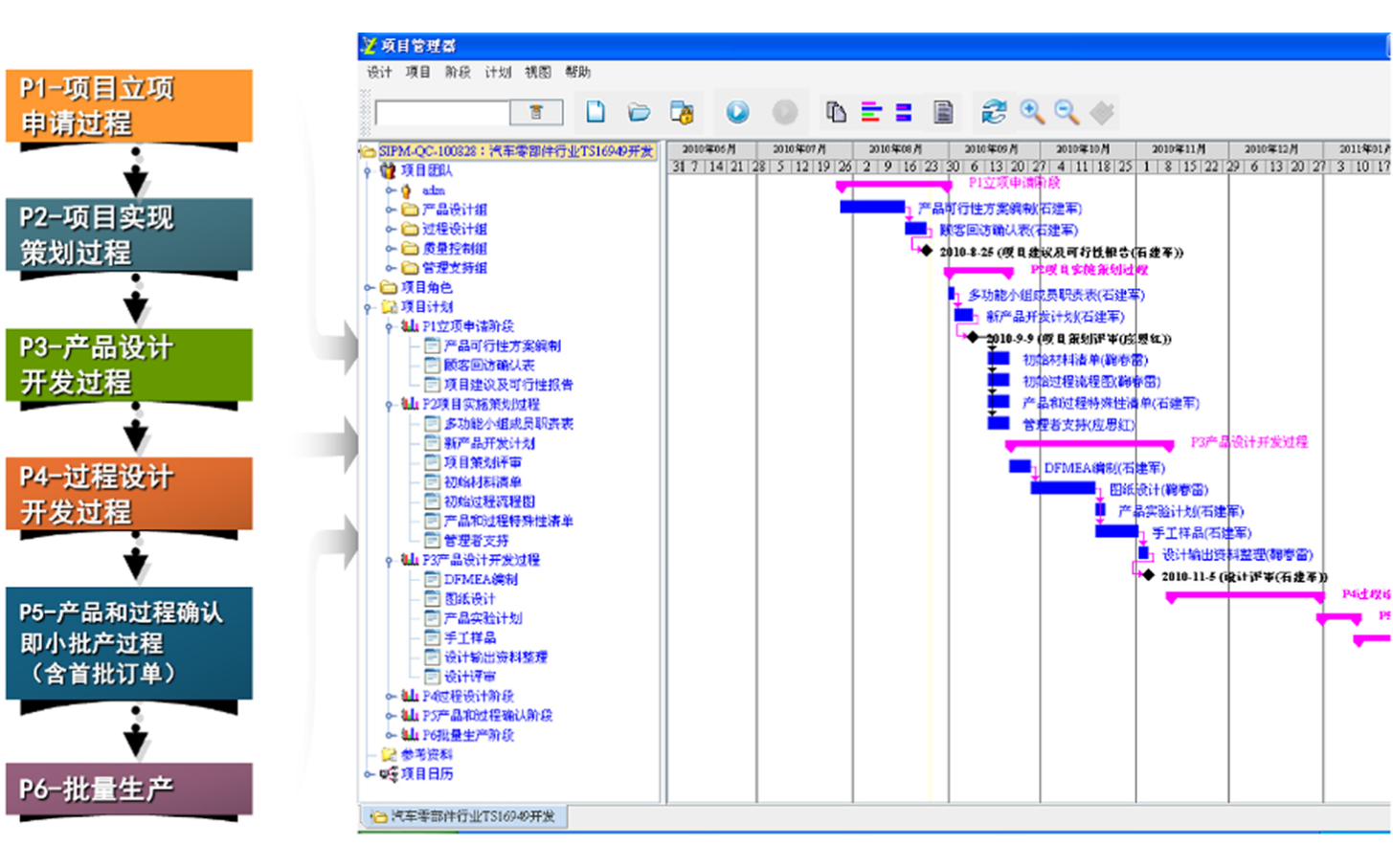

Through extensive practice and summarization,SIPM has developed a project management solution based on project templates,effectively achieving a perfect balance between usability and rigor in the project management process.It has become the optimal IT tool for implementing R&D processes.

By utilizing the engineering change solution provided by SIPM/PLM,not only are document versions and changes accurately recorded,but lifecycle management capabilities are also achieved for all data including materials and BOMs.This ensures comprehensive support for tracking the change history of all product-related data,enabling quick access to change history queries and dynamic change tracking.

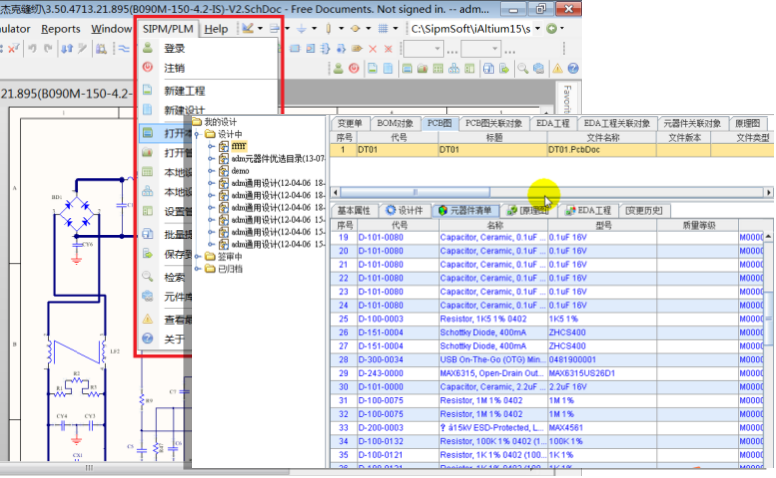

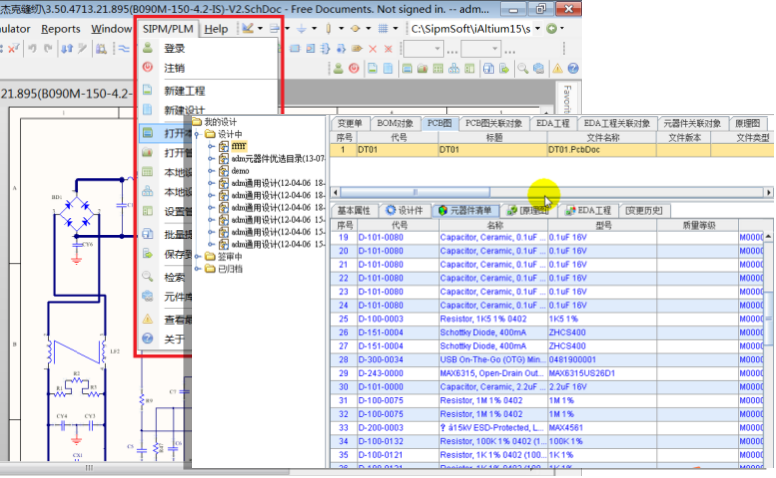

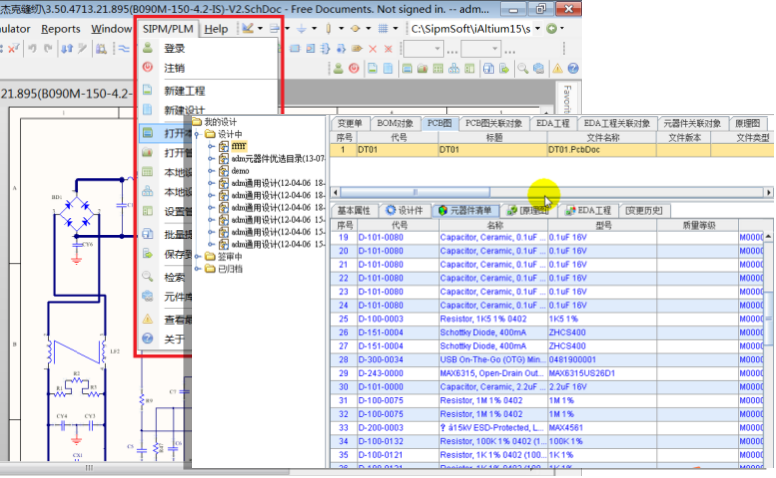

SIPM/PLM provides a comprehensive CAD integration solution based on an enterprise data bus,enabling full embedded information integration for mechanical and electronic design.In particular,its optimization technology for large and complex assemblies ensures bidirectional data exchange between design tools and the PLM system,providing powerful PLM support right from the beginning of drawing design.

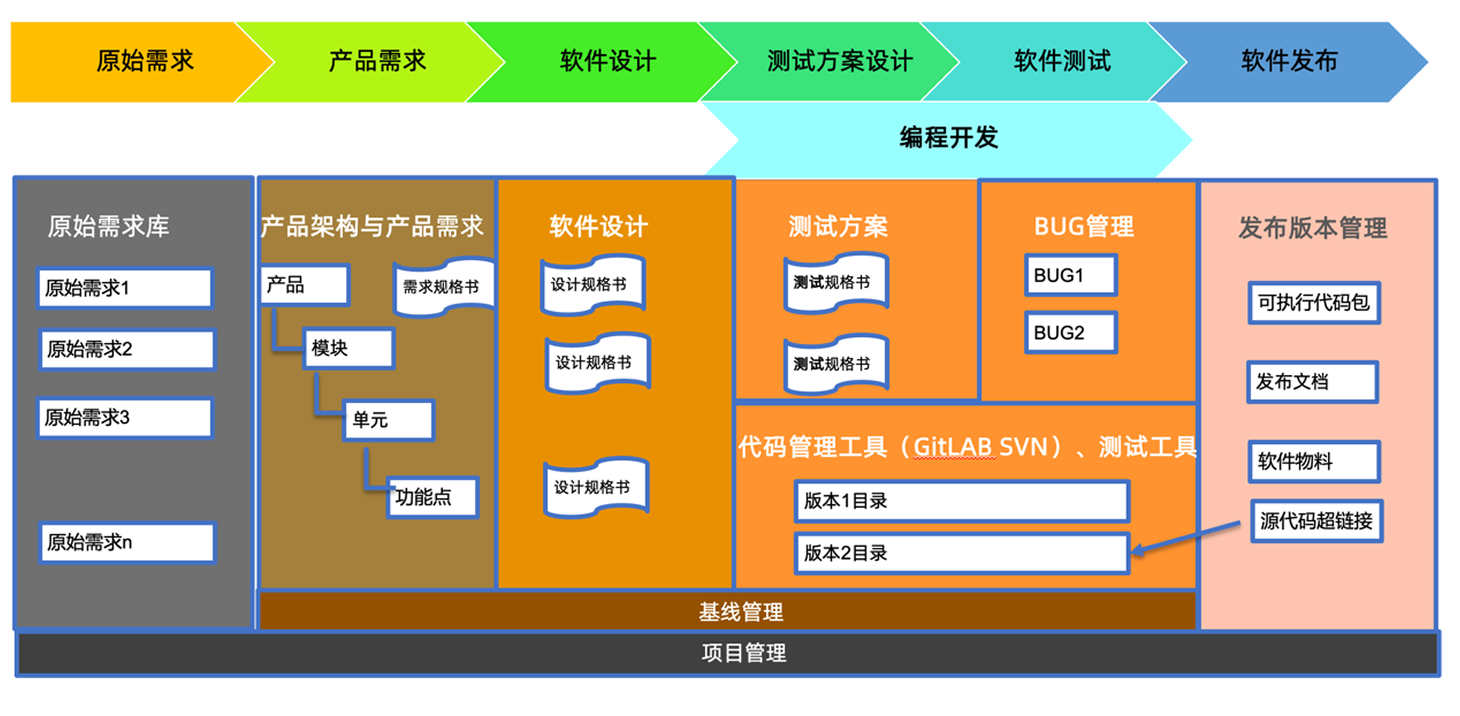

SIPM/PLM's software development management enables seamless integration of end-to-end data flows,effectively managing documentation and bug information throughout the entire development lifecycle—from requirements,design,and development to testing and release.Through standardized system architecture and modular design,it ensures software development complies with quality management system requirements,achieving comprehensive process control.All design data is fully traceable,enabling sharing and reuse of software development outcomes,and building a more flexible,enterprise-demand-oriented software development management system.

SIPM/PLM's unique technology for synchronized management of original electronic files and their shadow files ensures that shadow files are automatically updated whenever the original file is modified, and enables the conversion of shadow files into PDF format. All workflow-based approvals automatically generate handwritten-style electronic signatures, making the electronic document review and signing process truly trustworthy, reliable, and controllable. This technology also lays the foundation for paperless document distribution and sharing.

SIPM has conducted in-depth research into user operating habits and is committed to continuously improving the usability of SIPM/PLM. The system offers convenient drag-and-copy or drag-to-reference engineering functions, enabling seamless drag-and-drop interaction between the Windows Explorer and PLM file management, as well as between PLM data management and application tools such as Excel and SIPM/CAPP. With full support for copy and paste functionality, data entry and new design tasks become easy and efficient, providing engineers with a smooth and intuitive user experience.

Through close collaboration with customers and ERP implementers, SIPM has achieved seamless integration with mainstream domestic and international ERP systems such as SAP, Oracle, Infor, QAD, Kingdee, Yonyou, Digiwin, and Inspur.

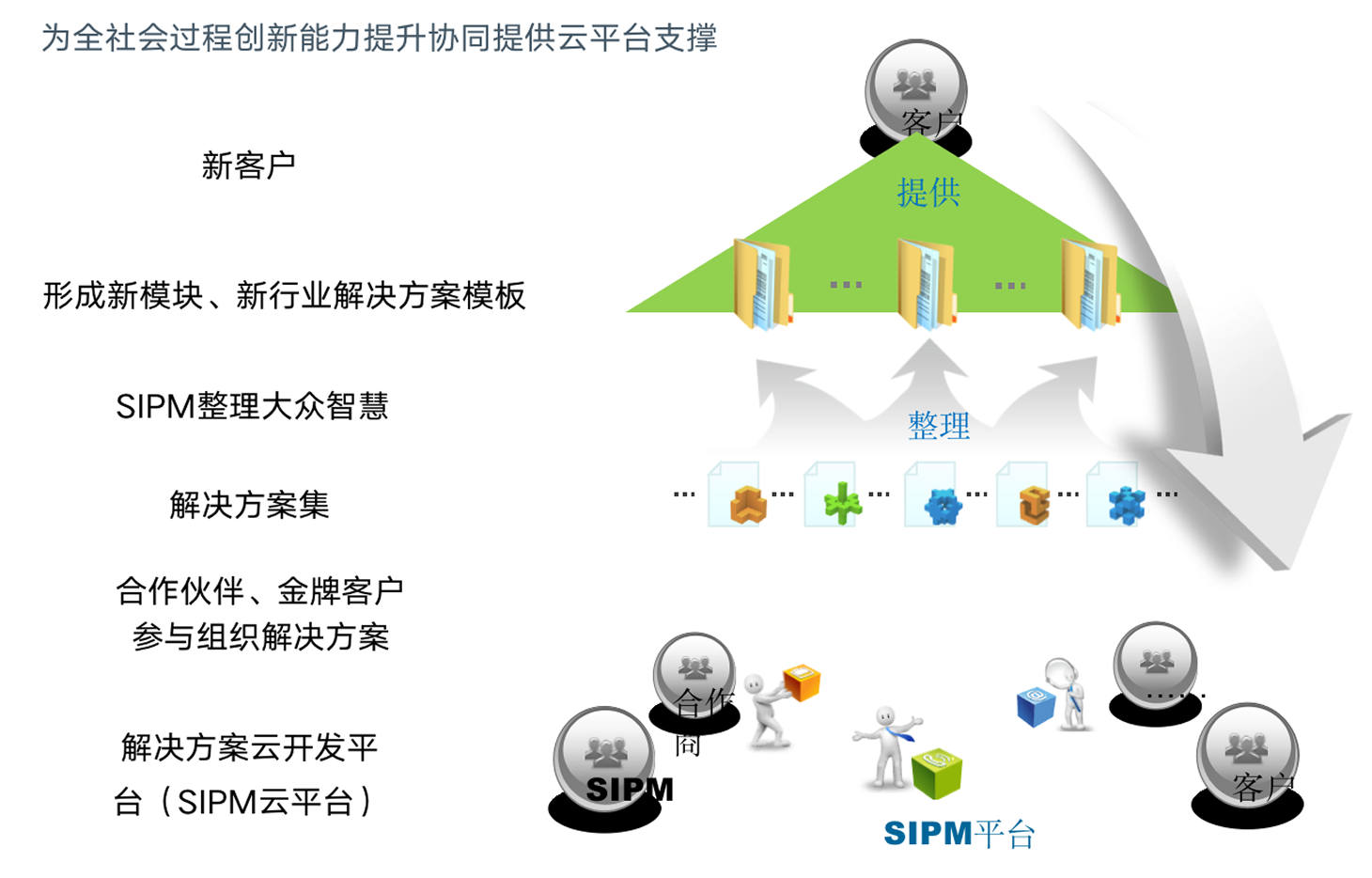

Through the iSIPM cloud strategy, SIPM enables customers to independently enhance their PLM systems. Over 350 customers are connected to the iSIPM cloud in real time every day, synchronizing management improvements with system upgrades. This continuously supports enterprise growth, empowers customers with full autonomy over system improvements, and ensures complete data transparency and accessibility for customers.

- Online Communication