Company Background

Sigmai Co., Ltd., established in 1998, is a nationally recognized high-tech enterprise specializing in the design, research and development, manufacturing, and sales of automotive shock absorbers and electronically controlled suspension systems. The company has total assets of RMB 1.8 billion, with a factory footprint exceeding 450 mu (approximately 300,000 square meters) and a total building area of over 450,000 square meters. It employs more than 3,200 staff members. Sigmai manufactures all core components in-house, making it the domestic industry leader with the highest self-manufacturing ratio among shock absorber producers.Its products cover more than 2,000 vehicle models across over 150 countries and regions, including European, American, Japanese, Korean, and Chinese domestic vehicles, encompassing over 20,000 individual part numbers.

As an industry pioneer, Sigmai aligns its strategy with the evolving trends in automotive development. By attracting top-tier technical talent, the company has successfully developed and mass-produced advanced products such as composite air-spring suspensions, magnetorheological dampers, and mono-tube self-adjusting shock absorbers. Sigmai holds more than 30 national patents, 22 of which have been officially registered as provincial-level scientific and technological achievements.The company maintains long-term collaborative R&D partnerships with renowned Chinese academic institutions, including Tsinghua University and Zhejiang University of Technology. Additionally, Sigmai co-established an academician workstation with Belarusian State University, laying a solid foundation for its technological advancement. The company also operates a provincially accredited Shock Absorber Research Institute and a CNAS-certified laboratory, equipped with over 100 sets of advanced R&D and testing equipment, providing comprehensive support and assurance to its customers.

Implementation of the SIPM/PLM project has achieved the following objectives:

-

Enhanced management capabilities and driven transformation at the Testing Center: Standardized testing operations, automated information management, and digitized resource management across the Testing Center.

-

Full alignment with ISO/IEC 17025 requirements: Provided modern tools necessary to meet these standards. While addressing practical operational needs, the project incorporated best practices from international laboratories to comprehensively elevate the Testing Center’s modernization level, align its operations with global benchmarks, and maintain ongoing ISO/IEC 17025 accreditation.

-

Platform-based management of experimental result data: Enabled unified data collection and centralized management, with real-time data capture during testing processes by lab technicians, facilitating comprehensive analysis of all test results.

-

Standardized document management: Established consistent and unified control over product-related documents—including engineering drawings, inspection standards, product specifications, technical documentation, product manuals, and coding rules—and implemented a formalized document management system.

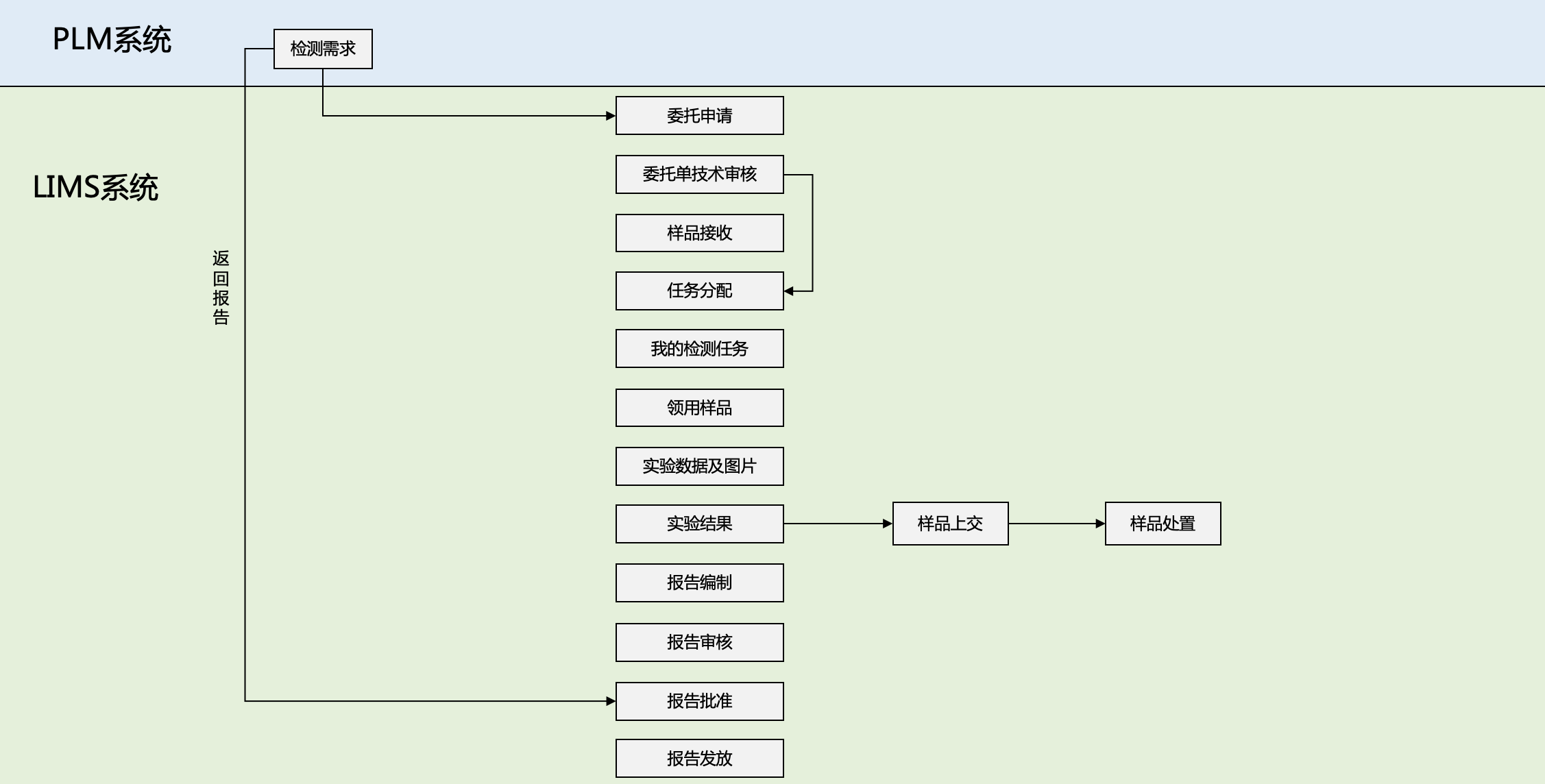

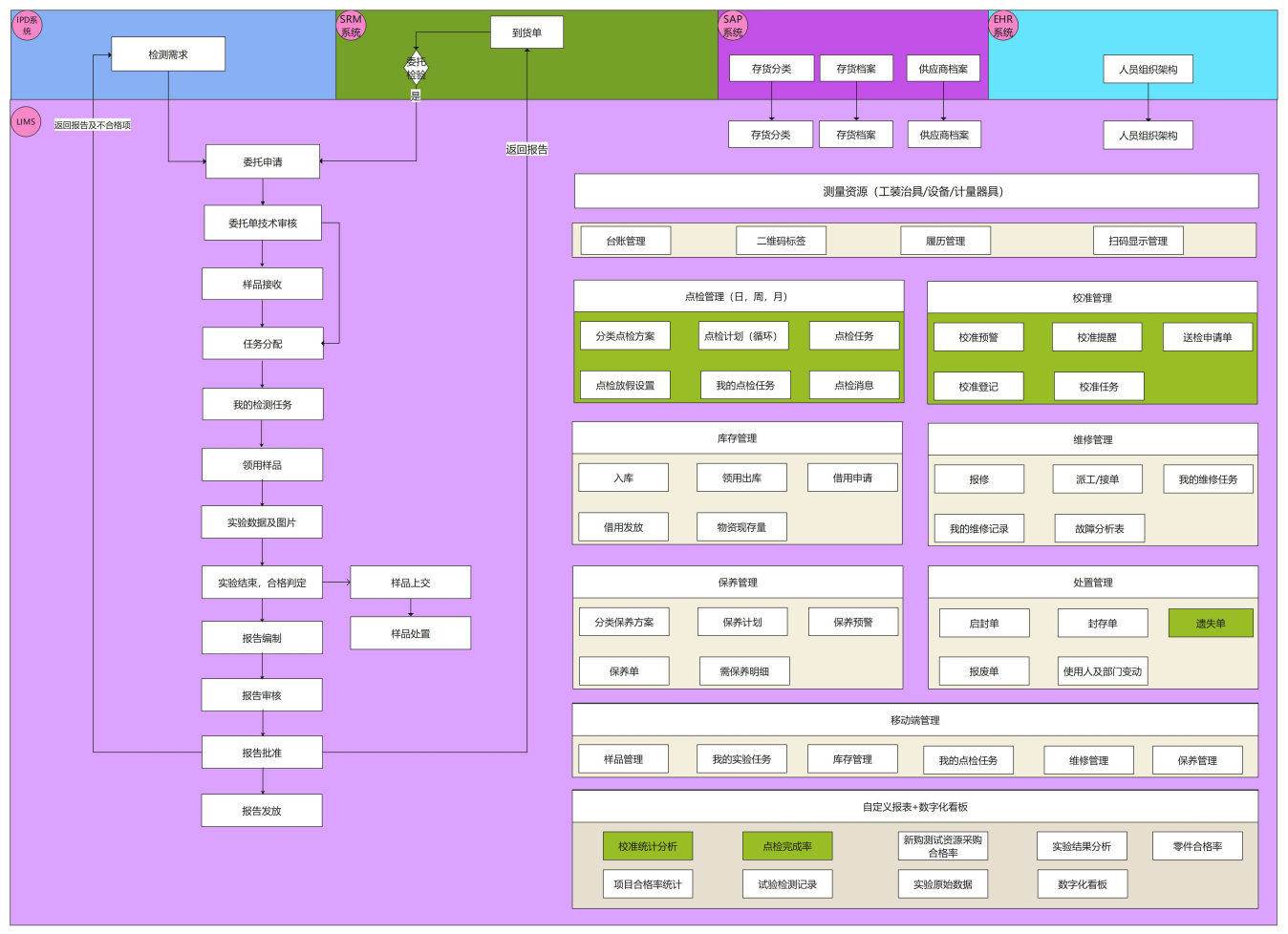

Business Landscape:

Business Landscape

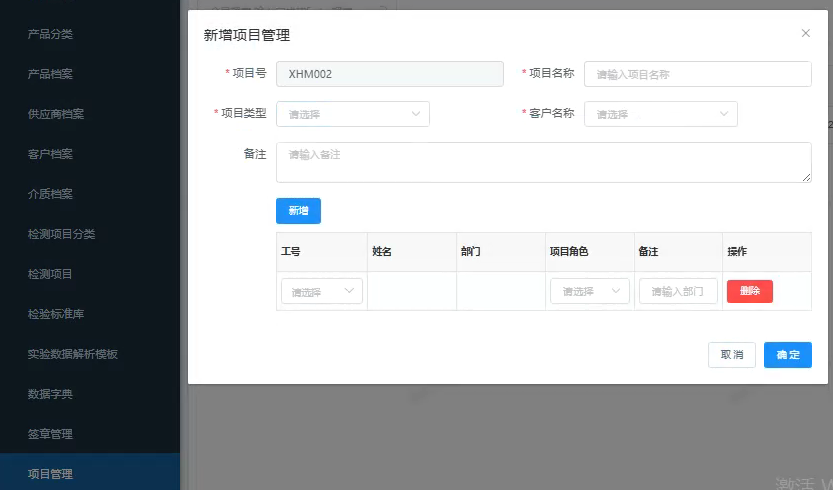

Project Management: Added a new project management module that distinguishes between large-scale and small-scale projects based on their type. For large-scale projects, the concept of a project team is introduced, allowing only members of the designated project team to conduct experiments for that project. This feature is particularly useful for scenarios where independent project teams are specifically formed for unique clients.

Project Management

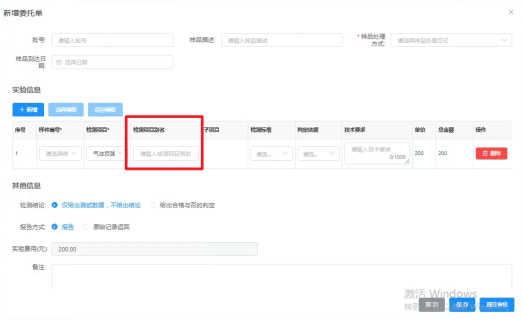

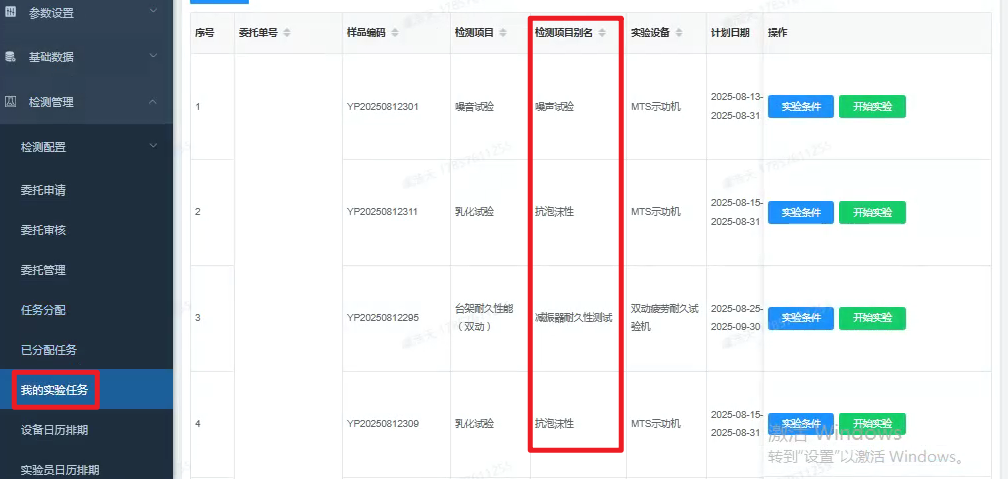

Test Item Alias: A new "Test Item Alias" field has been added to the work order and all other interfaces related to experimental tasks. Since different customers may use different names for the same test item, yet reports must be issued using the exact test item name specified by each customer, this new alias field effectively resolves inconsistencies in naming for the same test item across different clients.

Test Item Alias

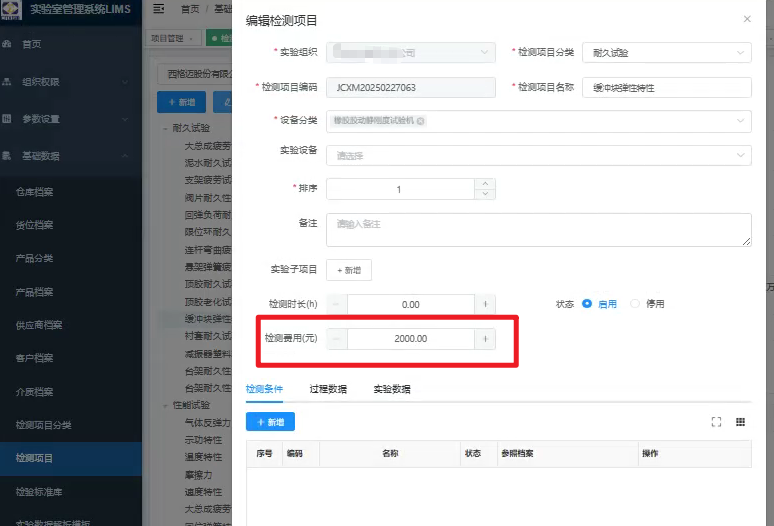

Testing Costs: Test items now include associated testing fees, which are used to track resource utilization by departments outside the laboratory and to evaluate the performance of lab technicians.

Testing Costs

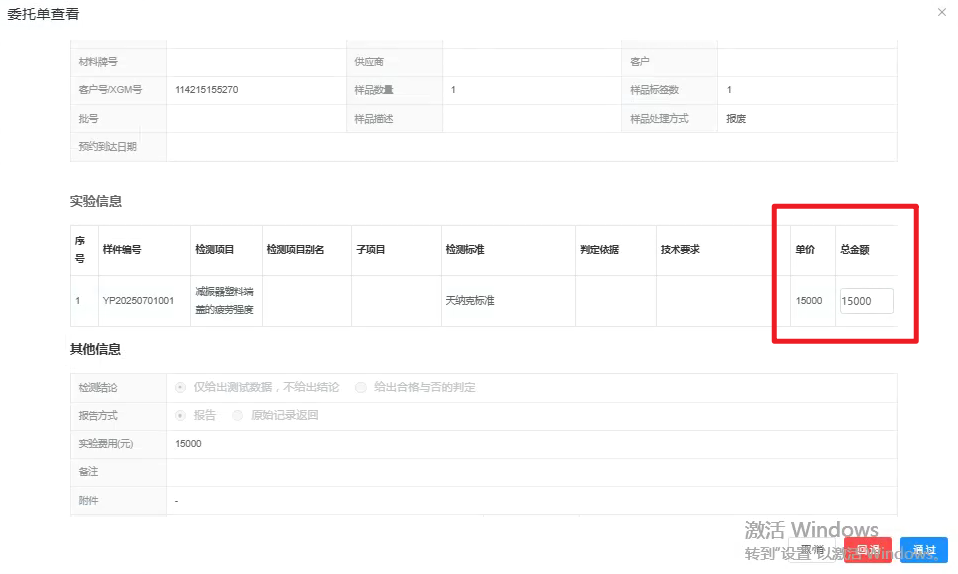

Review and Adjustment of Testing Fees:During the work order review process, authorized reviewers can now modify the testing fee. For certain environmental tests, multiple samples can be tested simultaneously under a single test run, incurring only one charge. Therefore, the total fee cannot always be calculated simply by multiplying the number of samples by the unit price of the test item. To address this, a new feature has been added that allows laboratory reviewers to adjust the testing fee during the review stage based on actual testing conditions, ensuring flexible and accurate billing instead of rigid, formulaic calculations.

Review and Adjustment of Testing Fees

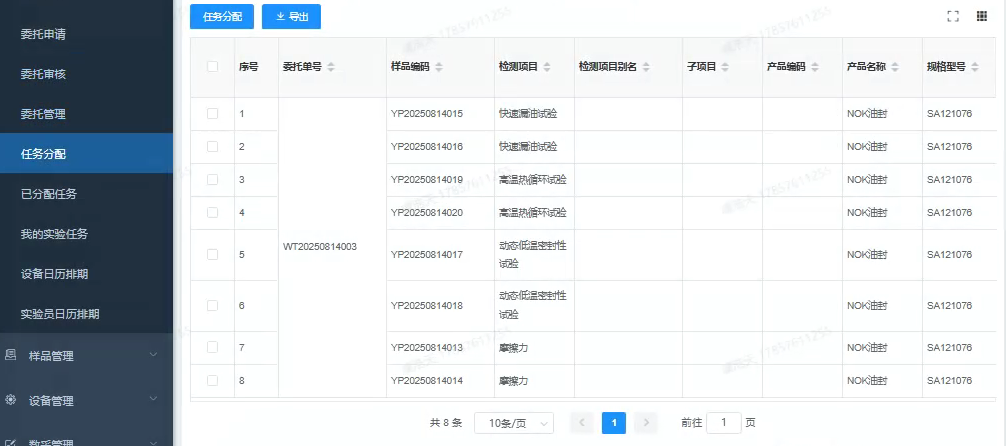

Dual Aggregation in Task Assignment:Unlike the previous system, which displayed each task as a separate data entry, the new task assignment interface features an automatic aggregation function. Tasks are now automatically grouped based on two dimensions: the same work order number and the same test item. This dual-level aggregation simplifies and streamlines the task allocation process for assigners.

Dual Aggregation in Task Assignment

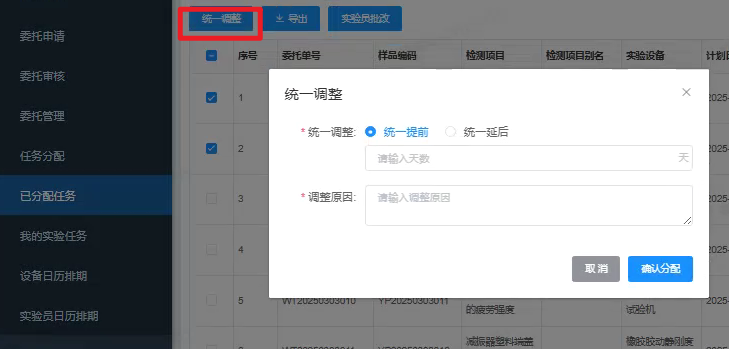

Bulk Adjustment of Assigned Tasks:For tasks that have already been assigned, the system now supports multi-select functionality, enabling users to uniformly advance or postpone selected tasks. This enhancement significantly improves the efficiency of task schedulers when adjusting task timelines.

Bulk Adjustment of Assigned Tasks

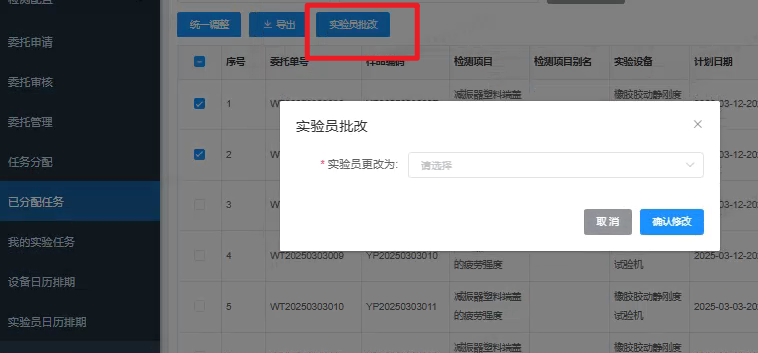

Batch Reassignment of Technicians for Assigned Tasks:For tasks that have already been assigned, the system now supports multi-select functionality, allowing users to uniformly reassign a different technician to the selected tasks. This feature significantly improves the efficiency of task coordinators when adjusting technician assignments.

Batch Reassignment of Technicians for Assigned Tasks

Technician Access to Attachments:Attachments uploaded to the work order are now carried over to the "My Test Tasks" interface, enabling technicians to easily view testing requirements and related documents.

Technician Access to Attachments

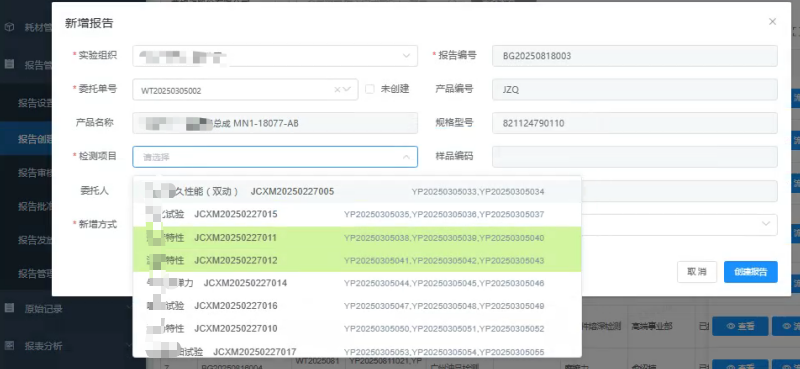

Report Generation by Test Item:For a single work order containing multiple test items, the system supports generating a separate report for each individual test item. Reissuing reports is also permitted; however, the system ensures that every report retains a unique report number.

Report Generation by Test Item

Report Upload via Attachment:To accommodate the diverse report formats used by laboratories—where such variation is permitted by administrators—the system now includes a feature allowing reports to be uploaded as attachments. After technicians finalize their reports offline, they can upload them into the system, where the reports then follow an online approval workflow, enabling end-to-end digital management of reporting processes.

Report Upload via Attachment

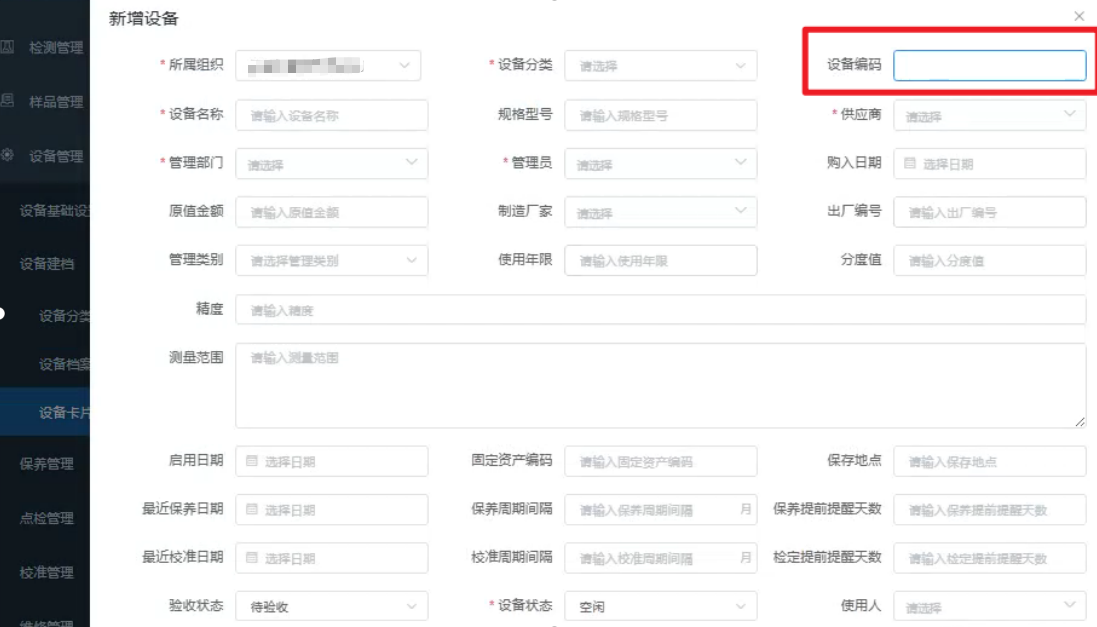

Manual Entry of Equipment Codes:Equipment codes can be manually entered, ensuring code uniqueness and addressing the current lack of standardized, sequential equipment coding within the organization.

Manual Entry of Equipment Codes

Customized Coding Rules:To link sample codes with work order numbers and report codes with test items, the system now supports the following enhancements:In sample numbering, users can select an option to insert the work order number into the sample code, with control over the starting position of the insertion;In report numbering, users can choose to embed the test item code into the report number, with configurable control over the exact insertion position.

Customized Coding Rules

Skip-Date Scheduling:A new "Skip-Date Schedule" feature has been added to accommodate weekends and public holidays. For automatically generated tasks—such as inspections, maintenance, and calibrations—the system will now reference the configured skip-date schedule and exclude designated non-working days when generating tasks. This prevents tasks from being scheduled on weekends or holidays, ensuring a more practical and user-friendly workflow.

Skip-Date Scheduling

Summary:

-

While fully complying with the ISO/IEC 17025 standard, the system enhances user convenience through features such as centralized data aggregation and unified task assignment. By simplifying operations—doing "less but better"—it reduces system complexity and minimizes time spent on administrative tasks, thereby significantly improving laboratory technicians’ productivity.

-

Through system integration, seamless data interoperability is achieved, enhancing both the efficiency and accuracy of data transmission.

-

Experimental result data is now managed on a unified digital platform—enabling standardized collection, centralized management, and real-time data capture during testing. This facilitates comprehensive analysis of all test results.